油(you)(you)脂污(wu)(wu)水(shui����)中(zhong)除含有(you)高濃度油(you)(you)脂外(wai),還含有(you)磷脂、皂等有(you)機(ji)物(wu)以及酸(suan)、堿、鹽(yan)和固(gu)態(tai)懸(xuan)浮物(wu),COD和BOD很高,同(tong)時油(you)(you)脂污(wu)(wu)水(shui)多為(wei)間歇排(pai)放,成(cheng)分復雜,pH值不穩定,水(shui)質水(shui)量變(bian)化(hua)幅度很大(da),對(dui��������)污(wu)(wu)水(shui)處理設施沖(chong)擊較大(da)。

油(you)脂(zhi)污(wu)水(shui)(shui)(shui)(shui)(shui)由格柵進(jin)入(ru)隔油(you)池(chi),經酸(suan)化(hua)隔油(you)處理后(hou)可(ke)回(hui)收大(da)量(liang)的油(you)脂(zhi),既可(ke)減(jian)輕后(hou)續(xu)處理工藝的有(you)(you)機負荷,同時(shi)還可(ke)回(hui)收有(you)(you)價(jia)值的油(you)脂(zhi)。污(w������u)水(shui)(shui)(shui)(shui)(shui)經過(guo)隔油(you)池(chi)去除表層(ceng)浮(fu)(fu)油(you)后(hou)進(jin)入(ru)中(zhong)和(he)調(diao)節(jie)池(chi),調(diao)節(jie)池(chi)污(wu)水(shui)(shui)(shui)(shui)(shui)再用(yong)泵(beng)泵(beng)入(ru)氣浮(fu)(fu)池(chi),去除污(wu)水(shui)(shui)(shui)(shui)(shui)中(zhong)的浮(fu)(fu)化(hua)油(you)、磷脂(zhi)、皂腳、COD等(deng)。出(chu)水(shui)(shui)(shui)(shui)(shui)進(jin)入(ru)厭氧(yang)(yang)池(chi),利(li)用(yong)厭氧(yang)(yang)菌的酸(suan)化(hua)水(shui)(shui)(shui)(shui)(shui)解(jie)作(zuo)用(yong),將污(wu)水(shui)(shui)(shui)(shui)(shui)中(zhong)的高(gao)分(fen)(fen)子有(you)(you)機物(wu)斷鏈分(fen)(fen)解(jie)為(wei)有(you)(you)機酸(suan)等(deng)小分(fen)(fen)子有(you)(you)機化(hua)合(he)物(wu),以利(li)于后(hou)續(xu)好氧(yang)(yang)生(sheng)(sheng)化(hua)降(jiang)解(jie),厭氧(yang)(yang)池(chi)出(chu)水(shui)(shui)(shui)(shui)(shui)進(jin)入(ru)SBR生(sheng)(sheng)物(wu)接(jie)觸氧(yang)(yang)化(hua)池(chi),水(shui)(shui)(shui)(shui)(shui)中(zhong)各種(zhong)有(you)(you)機污(wu)染(ran)物(wu)通(tong)過(guo)好氧(yang)(yang)生(sheng)(sheng)物(wu)的氧(yang)(yang)化(hua)分(fen)(fen)解(jie)作(zuo)用(yong)被轉化(hua)為(wei)CO2,HO2等(deng)無害物(wu)質(zhi),從(cong)而達(da)到(dao)去除污(wu)染(ran)物(wu)的目的。出(chu)水(shui)(shui)(shui)(shui)(shui)進(jin)中(zhong)間池(chi),經投加混凝(ning)劑后(hou)進(jin)入(ru)反(fan)應池(chi),進(jin)行充分(fen)(fen)混合(he),然(ran)后(hou)經沉淀池(chi),泥水(shui)(shui)(shui)(shui)(shui)自(zi)然(ran)分(fen)(fen)離后(hou)進(jin)入(ru)生(sheng)(sheng)物(wu)碳過(guo)濾器,一部分(fen)(fen)殘余有(you)(you)機物(wu)被活性炭(tan)吸(xi)附截留,同時(shi)被生(sheng)(sheng)物(wu)降(jiang)解(jie)。此時(shi)出(chu)水(shui)(shui)(shui)(shui)(shui)完全達(da)到(dao)回(hui)用(yong)的要求,可(ke)以重(zhong)新作(zuo)為(wei)循環冷卻水(shui)(shui)(shui)(shui)(shui)和(he)雜用(yong)水(shui)(shui)(shui)(shui)(shui),或直接(jie)達(da)標排放。

氣浮池、沉淀池的污�������(wu)泥定期排入污(wu)泥干化(hua)池,經干化(hua)后泥餅(���������bing)外(wai)運填埋,濾(lv)液返回(hui)調節池重新(xin)處(chu)理。

厭(yan)(yan)(yan)氧(yang)(yang)生(sheng)物處(chu)(chu)理(li)(li):其優(you)勢在(zai)于(yu)它能處(chu)(chu)理(li)(li)較(jiao)高(gao)濃(nong)度的(de)有(you)(you)機(ji)污(wu)(wu)(wu)水(shui)(shui)(shui)而不(bu)必稀釋(shi)進水(shui)(shui)(shui)濃(nong)度。目前厭(yan)(yan)(yan)氧(yang)(yang)處(chu)(chu)理(li)(li)工藝(yi)(yi)較(jiao)多(duo)采(cai)用(yong)升流式(shi)厭(yan)(yan)(yan)氧(yang)(yang)污(wu)(wu)(wu)泥床(UASB),厭(yan)(yan)(yan)氧(yang)(yang)生(sheng)物濾(lv����)床(AF),厭(yan)(yan)(yan)氧(yang)(yang)復合(he)床(AFB)及普通厭(yan)(yan)(yan)氧(yang)(yang)消化(hua)池(chi)等,一般采(cai)取中溫消化(hua)的(de)方(fang)式(shi)。厭(yan)(yan)(yan)氧(yang)(yang)處(chu)(chu)理(li)(li)后的(de)污(wu)(wu)(wu)水(shui)(shui)(shui)中COD值還較(jiao)高(gao),一般需(xu)后接好(hao)氧(yang)(yang)處(chu)(chu)理(li)(li)工藝(yi)(yi)才能使(shi)污(wu)(wu)(wu)水(shui)(shui)(shui)水(shui)(shui)(shui)質(zhi)達標。盡管厭(yan)(yan)(yan)氧(yang)(yang)工藝(yi)(yi)在(zai)國內(nei)植物油廠污(wu)(wu)(wu)水(shui)(shui)(shui)處(chu)(chu)理(li)(li)方(fang)面已(yi)有(you)(you)多(duo)項工程投(tou)入運行,但總(zong)體說來目前國內(nei)已(yi)有(you)(you)的(de)生(sheng)物處(chu)(chu)理(li)(li)工藝(yi)(yi)大部(bu)分還是好(hao)氧(yang)(yang)處(chu)(chu)理(li)(li)工������藝(yi)(yi),究其原(yuan)因一是厭(yan)(yan)(yan)氧(yang)(yang)法存在(zai)啟動時(shi)間長,操作管理(li)(li)處(chu)(chu)理(li)(li)復雜等缺(que)點。

好氧(yang)生物(wu)處(chu)理(li):好氧(yang)生物(wu)處(chu)理(li)工藝(yi)������是(shi)目前(qian)植(zhi)物(wu)油脂廠污(wu)水生物(wu)處(chu)理(li)中��������最重要的工藝(yi),其中常用的有:

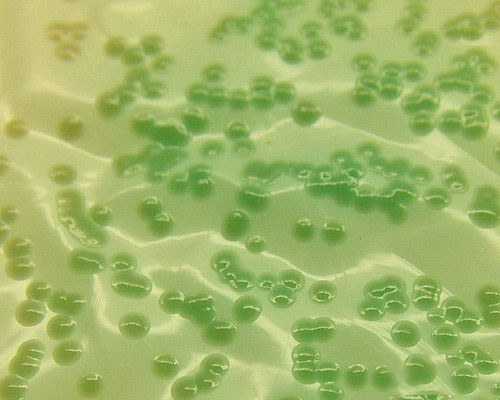

活性污(wu)泥(ni)�������法:活性污(wu)泥(ni)法處理(li)油(you)脂(zhi)污(wu)水工(gong)藝(yi)是在(zai)有氧條(tiao)件下采取連續循(xun)環(huan)的(de)(de)微生物生長,以有機物(油(you)脂(zhi))作為(wei)惟(wei)一碳源(yuan),轉化并(bing)合(he)成(cheng)(cheng)為(wei)微生物體內有機成(cheng)(cheng)分(fen)的(de)(de)方式達到(dao)降解油(you)脂(zhi)的(de)(de)目的(de)(de)。該工(gong)藝(yi)是應用較廣泛(fan)的(de)(de)好氧工(gong)藝(yi),但耐沖擊負荷差、容積負荷低、體積大、易造成(cheng)(cheng)污(wu)泥(ni)膨(peng)脹(zhang)等缺點。

SBR法:SBR法是(shi)活性污(wu)泥工藝的變(bian)型(xing),該(gai)工藝具(ju)有自動化程度高(gao)、抗沖擊(ji)能力強、不(bu)產(chan)生污(wu)泥腫脹等優點(dian)。由于SBR法省去(qu)了沉(chen)淀和污(wu)泥回流部分,因而可降低(di)一次(ci)性工程投資和運(yun)行(xing)費用。盡管SBR法有上述優點(dian),但其也存在不(bu)適(�����shi)應高(gao)濃(nong)度污(wu)水(shui)和連(lian)續流污(wu)水(shui)處理、要(yao)求自控(kong)系統較高(gao)、操作復雜等缺點(dian)。

生物(wu)(wu)(wu)膜(mo)(mo)(mo)法(fa)(fa):生物(wu)(wu)(wu)膜(mo)(mo)(mo)法(fa)(fa)是在(zai)活性(xing)污泥法(fa)(fa)基礎(chu)上改進的一種(zhong)好氧工(gong)(gong)藝。與活性(xing)污泥法(fa)(fa)中微(wei)生物(wu)(wu)(wu)呈懸浮狀態不同(tong),生物(wu)(wu)(wu)膜(mo)(mo)(mo)法(fa)(fa)中的微(wei)生物(wu)(wu)(wu)都是附著生長在(zai)膜(mo)(mo)(mo)表面,由于(yu)曝氣(qi)設備設在(zai)填(tian)料之下,曝氣(qi)可以起到攪(jiao)拌作用,使得生物(wu�����)(wu)(wu)膜(mo)(mo)(mo)更新(xin)加快、活性(xing)增加,因而(er)生物(wu)(wu)(wu)膜(mo)(mo)(mo)工(gong)(gong)藝處(chu)理污水(shui)的效果和容積(ji)負(fu)荷都比活性(xing)污泥法(fa)(fa)有(you)較大提高,目前國內(nei)油脂(zhi)(zhi)污水(shui)好氧生物(wu)(wu)(wu)處(chu)理系統(tong)多(duo)采用生物(wu)(wu)(wu)膜(mo)(mo)(mo)工(gong)(gong)藝。生物(wu)(wu)(wu)膜(mo)(mo)(mo)法(fa)(fa)工(gong)(gong)藝主(zhu)要適用于(yu)油脂(zhi)(zhi)污水(shui)水(shui)量不大,場地較小的情況。

油(you)(you)脂(zhi�������)(zhi)污水(shui)要系統(tong)化綜(zong)合(he)處(chu)理(li)才會(hui)有顯著的(de)(de)凈化效(xiao)果,僅靠微(wei)(wei)(wei)生(sheng)物(wu)簡單處(chu)理(li)不會(hui)顯著生(sheng)效(xiao)。微(wei)(wei)(wei)生(sheng)物(wu)單獨使(shi)用(yong)主(zhu)要是(shi)放在經常(chang)被油(you)(you)脂(zhi)(zhi)堵塞,用(yong)傳(chuan)統(tong)方法(fa)又不易清理(li)的(de)(de)管(guan)道(dao)等處(chu),微(wei)(wei)(wei)生(sheng)物(wu)只要部分(fen)分(fen)解(jie)油(you)(you)脂(zhi)(zhi),將油(you)(you)脂(zhi)(zhi)粘度降下來即可(ke)達到(dao)疏通的(de)(de)目(mu)的(de)(de),同(tong)時,微(wei)(wei)(wei)生(sheng)物(wu)又將管(guan)道(dao)中產(chan)(chan)臭(chou)氣的(de)(de)有機質以不產(chan)(chan)臭(chou)的(de)(de)方式分(fen)解(jie),達到(dao)除臭(chou)目(mu)的(de)(de)。